How Clothes Are Made.

garment /ˈɡɑːm(ə)nt/, noun: an item of clothing. — Oxford English Dictionary

Every garment you wear was made by hand.

Not metaphorically - literally.

Each seam was guided by fingers. Each button sewn with thread pulled through cloth. Each curve once lay flat, then was cut, shaped, and stitched with human hands at every step. And often, the more hands a garment passes through, the more rushed those hands must be - each pair doing just one small task, over and over, faster and faster, for less. In this way, the garment becomes less whole - not more.

Pause and look at what you’re wearing right now.

Can you imagine the hands? How fast did they move? Can you see the care - or the absence of it?

Do you know how your clothes are made?

The Foundation

What is a garment?

At its simplest, a garment is a functional clothing object. It’s made from fabric that has been shaped to fit the human body. While styles and techniques vary, most garments are made from multiple flat pieces of cloth that are joined together to create volume, shape, and movement. These pieces are stitched together using seams and finished with hems, fastenings, and sometimes decorative or functional details. The process of transforming fabric into clothing is a mix of design, mathematics, craftsmanship, and intention.

Most clothing falls into one of a few key categories:

Tops (shirts, blouses, t-shirts, jackets)

Bottoms (trousers, skirts, shorts)

Dresses & Jumpsuits (one-piece garments)

Outerwear (coats, blazers, rainwear)

Each of these has its own construction logic. A shirt typically has a collar and button placket. Trousers require a fly, waistband, and often pockets. Dresses combine top and bottom structures. Learning to “see” these components helps decode how a piece was made - and why it might wear the way it does.

-

Fabric is the starting point for any garment. It’s made by knitting or weaving yarns — which themselves are spun from fibers, either natural (like cotton, wool, silk) or synthetic (like polyester, nylon, acrylic). The structure of the fabric (woven vs. knit) affects how it stretches, drapes, and moves. Natural fibers tend to breathe better and biodegrade, while synthetics are often cheaper but shed microplastics and hold odors. Understanding fabric types helps us predict how clothes will wear, age, and feel.

-

A pattern is a template used to cut fabric into shapes that, when sewn together, form a garment. It’s like a blueprint for clothing. Each pattern piece corresponds to a part of the body - front bodice, sleeve, back leg, etc. Patterns are typically drawn on paper and then traced onto fabric before cutting. Even simple garments often require 4–10 pieces. The cut determines fit and silhouette, and small changes in shape can dramatically alter how a garment sits on the body.

-

Seams are where two pieces of fabric are joined together. While we often overlook them, seams are the skeleton of a garment. Different seam types serve different functions:

Plain seams are the most basic, often overlocked (serged) to stop fraying.

French seams enclose raw edges, common in delicate fabrics.

Flat-felled seams (like those on jeans) are durable and neat.

Strong seams help garments last longer and handle movement without tearing. Visible topstitching can also add decorative detail.

-

Designers and makers use construction techniques to add shape, volume, and detail. Some common techniques include:

Darts - small folds that shape fabric around curves (like busts or hips).

Pleats - folded fabric for volume or movement.

Gathers - bunching fabric to create fullness.

Panels - multiple fabric sections sewn to create shape or design.

These choices impact how a garment fits and flows, as well as how long it takes to make.

-

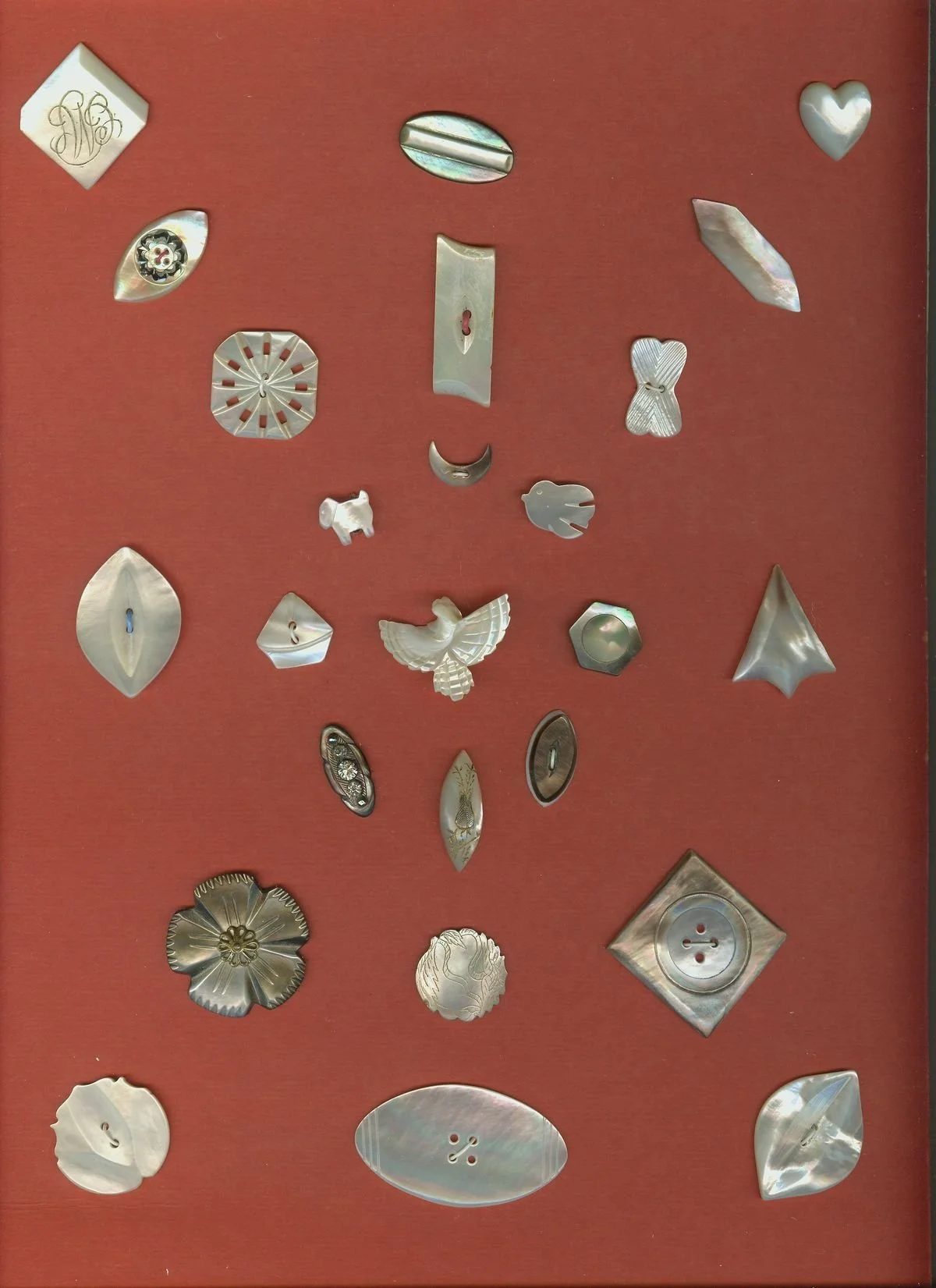

Item description

-

Closures are how we get in and out of clothing. Buttons, zippers, hooks, snaps, ties, and drawstrings all serve this purpose. The choice of closure affects not just functionality, but also the feel and style of the garment. For example, a zip might be sleek and minimal, while a row of buttons can become a feature. Closures are often the most technically challenging part of garment construction.

-

Hems are the final finish to a garment’s edges - the bottom of a shirt, the cuffs of a sleeve, or the neckline. Hemming prevents fraying and helps a garment hang properly. There are many techniques, from simple turned-up hems to blind stitching or binding. Well-finished edges don’t just look better; they add to the durability and comfort of a piece.

Step-by-Step Overview

-

Cloth is flat. Bodies are not. The magic of garment construction lies in turning two-dimensional fabric into three-dimensional form. This is done through shaping techniques like darts, panels, seams, and pattern curves. Even a simple sleeve cap is curved to sit comfortably over a rounded shoulder. When we understand how this shaping works, we begin to see how certain garments flatter or restrict, fit closely or hang loose. The difference between a structured blazer and a relaxed tee isn’t just fabric - it’s architecture.

-

Movement in clothing comes from both the cut and the fabric. Looser cuts and lightweight fabrics offer fluidity and drape. Tailored garments, meanwhile, use tension and precision to hold shape - hugging the body in specific places while allowing room in others. Pleats allow trousers to expand when walking. Bias cuts (diagonal to the grain) stretch slightly and cling to curves. Understanding these dynamics lets us recognize when a piece has been thoughtfully made for both style and wearability.

Design and Fit

-

Quality is often hidden in the details. A well-made garment typically features:

Even, tight, and straight stitching

Reinforced stress points (like bar tacks at pocket corners)

Cleanly finished seams

Secure closures

Balanced hems that don’t twist

These might not be flashy features, but they indicate care - and garments that are more likely to last through wear and washing.

-

Stitching is like the handwriting of a garment. Look closely: are the stitches even and secure? Or are they loose, wobbly, or pulling at the fabric? Loose or broken threads are signs of poor or rushed construction. Stitches that are too long might unravel quickly, while overly short stitches can pucker the fabric. If a garment looks like it’s already straining at the seams in-store, it probably won’t last long at home.

-

Some clothes are designed to be fixed. Others, sadly, are not. Garments with clean seam allowances and accessible linings are easier to take in, let out, or patch. Fabrics that fray heavily or are fused with adhesives can be much harder to repair. When we know what to look for, we can choose clothes that grow with us - not just in size, but through the seasons of our lives.

Durability and Repair

-

When we understand how clothes are made, we stop being passive consumers and start becoming active participants. We begin to see beyond the surface - asking how long something will last, how it might age, and how it could be cared for or repaired. We also become more forgiving of small imperfections and more aware of the labour involved. With this knowledge, buying becomes more intentional, and wearing becomes more mindful.

-

Most people are never taught how their clothes are made - and that gap keeps us disconnected. But learning even a little about garment construction opens the door to better decisions: slower shopping, thoughtful ownership, deeper value. It encourages a shift from impulse to intention. From endless replacement to respectful repair. When we know more, we ask more. And when we ask more, we change the system from within.

-

Start with your senses. Feel the fabric - does it have weight, structure, or softness that feels considered? Look closely at the stitching: are the seams straight, even, and secure? Are there stray threads or signs of stress already forming? Check closures: do zippers run smoothly, are buttons stitched on firmly, and are buttonholes cleanly finished? Turn the garment inside out if you can. Quality often hides in the parts not meant to be seen. Well-made clothes speak quietly, but with clarity.

-

Both are ways to finish the inside edges of a garment so the fabric doesn’t fray.

Overlocking (also called serging) uses a special machine to bind the edges quickly. It's common in mass production - fast and functional.

French seams, on the other hand, hide the raw edge entirely by sewing the seam twice - once wrong sides together, then right sides together. It’s slower and uses more fabric, but it creates a cleaner, longer-lasting finish. You’ll often find French seams in delicate or high-quality garments.

Knowing the difference helps you spot when extra care (or shortcuts) were taken.

-

Longevity comes down to three things: fabric, construction, and use. Natural fibres like linen, wool, and denim tend to age well when cared for. Garments with reinforced seams, quality stitching, and thoughtful finishes are less likely to fall apart under stress. But how we treat our clothes matters too - frequent washing, stretching, or ignoring small repairs all reduce lifespan. Some clothes are built for the long haul. Others are designed for quick turnover. Learning to tell the difference helps us invest more wisely.

-

Often, yes. But it depends on the garment and your skill level. Simple repairs like sewing on buttons, patching small holes, or restitching seams are beginner-friendly. Stretchy fabrics or overlocked edges can be trickier but not impossible. Clothes made with natural fibres and traditional seams are generally easier to fix than synthetics or bonded materials. Even if you’re new to sewing, small acts of mending - a stitched tear, a reinforced strap - can bring confidence and connection. Start where you are.

-

It’s not just price. “Cheap” clothes often rely on fast production, low-cost synthetic materials, and minimal quality control. They may feel scratchy, flimsy, or out of balance on the body. “Crafted” clothes, by contrast, reflect time, skill, and intention. They feel grounded - in weight, fit, and design. You can sense the difference even if you can’t name it. And while crafted doesn’t always mean expensive, it almost always means thoughtful. Slowing down to notice those details changes how we dress - and how we consume.

-

Construction is where ethics becomes visible. A well-constructed garment suggests time, skill, and fairer working conditions. Sloppy or rushed construction often signals the opposite - factories pushed to produce more for less, with little regard for garment workers or longevity. Ethical fashion values the process, not just the product. By learning to read construction, we develop an eye for care, effort, and respect. It becomes easier to choose clothes that honour both the maker and the wearer.

Why If Matters

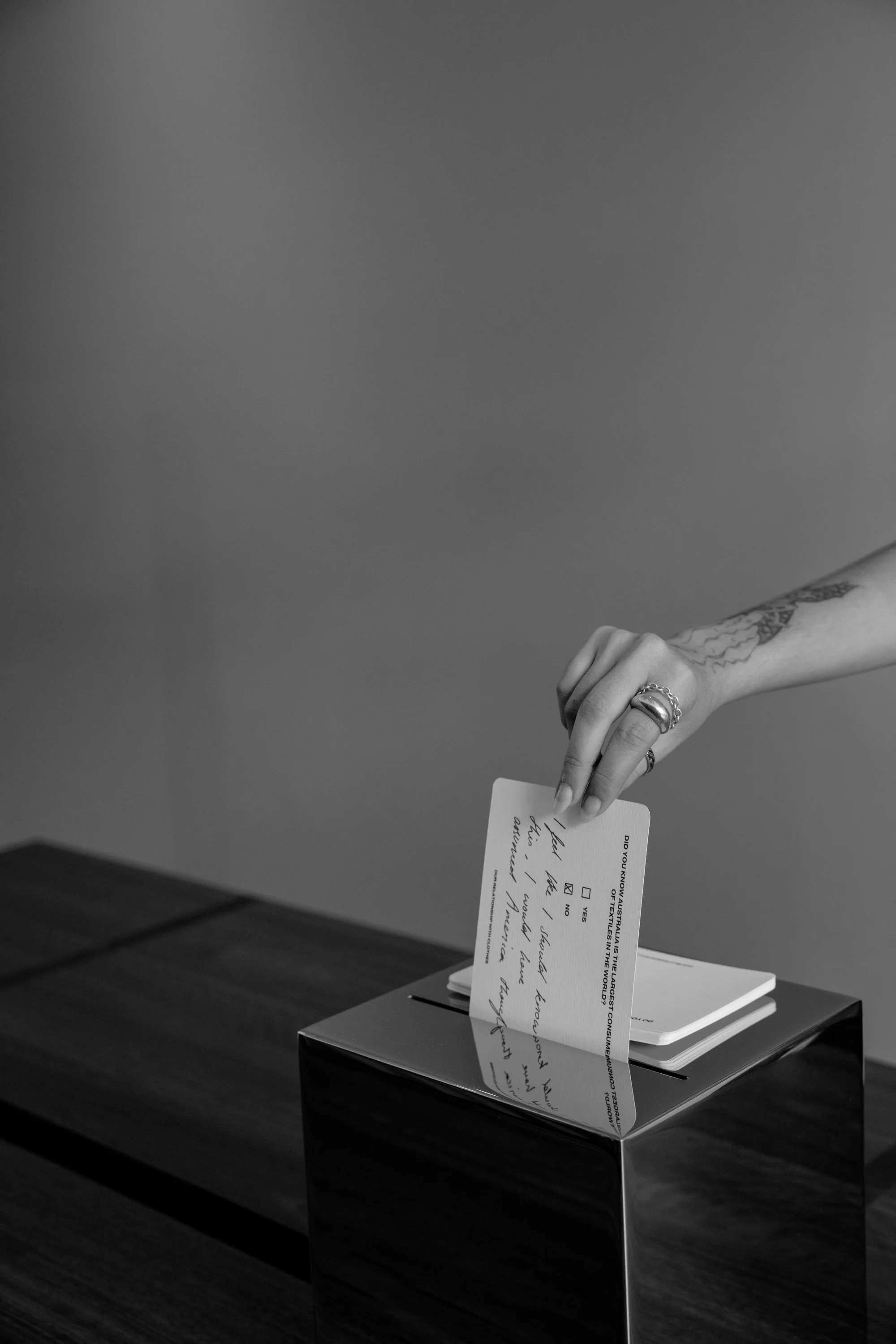

Creating change, one question at a time.

Participate

The Our Relationship With Clothes (O.R.W.C.) project is a space for everyone. Whether you’re already on the path to understand your relationship with fashion, wanting to repair it or just beginning to explore how clothes make you feel. This community is here to meet you where you are, normalising asking questions, having conversations and listening from a place of love and respect.

We believe in progress, not perfection.